Barbara Scollin, grandniece of Major Gen. Kenneth D. Nichols continues her series on his life.***Ample reasons, most notably leadership skills, personality traits and qualifications, led to choosing General (then Colonel) Kenneth D. Nichols as deputy district engineer and subsequently as district engineer of the Manhattan Engineer District (MED). In this capacity he had supervision of the research and development connected with, and the design, construction and operation of all plants required to produce plutonium-239 and uranium-235, including the construction of the towns of Oak Ridge, Tennessee, and Richland, Washington.

Dr. A.H. Compton’s Chancellor Inauguration, Washington University, 1951. Compton makes good on his champagne bet with seated, from left, Maj Gen Leslie Groves, Vannevar Bush, Enrico Fermi, Brigadier Gen. Kenneth Nichols, George Peagram and Lyman Briggs; standing, Charles Allen Thomas, James Conant, A.H. Compton, Eugene Murphree, and Crawford Greenewalt.

The responsibility of his position was massive as he oversaw a workforce of both military and civilian personnel of approximately 125,000; his Oak Ridge office became the center of the wartime atomic energy’s activities. He also was responsible for internal security operations in the production facilities that helped keep the development of the atomic bomb secret.

In this 14th installment of several articles covering the life and accomplishments of Kenneth D. Nichols, his diplomacy skills are stretched thin over plutonium production.

At a June 1942, S-1 committee meeting Dr. Arthur Holly Compton and Col. Kenneth Nichols began a close working relationship and lifelong friendship (see sixth article). Nick was impressed with AH’s “sincerity of purpose.” Compton, University of Chicago’s Physics Department chairman and head of the Metallurgical Laboratory (“Met Lab”), was described by Nick as, “most pleasant to work with. I soon developed tremendous admiration for Compton.

“I have never dealt with anyone else who had the mental capacity, the high ideals and moral standards, and the determination to achieve an objective, combined with such great consideration of others, as he had. He always was extremely cooperative and had a keen understanding of the Army’s problem of dealing with the variety of individuals and organizations involved in the project. He reorganized the Met Lab to assist better in the overall effort to produce atomic weapons at the earliest possible date. He also cooperated in our efforts to administer the project to account for expenditures and avoid waste or corruption.”

Scientists theorized plutonium-239 might offer a more efficient alternative to uranium-235 in a bomb. Compton and Nichols discussed the plutonium process in July 1942, and explored the process with DuPont engineers.

Col. Frank Matthias, Deputy District Engineer (HEW), Col. Kenneth D. Nichols, District Engineer (MED). The Manhattan Engineer District emblem is on the plane behind Matthias.

The Sept. 13, 1942, S-1 meeting at the Bohemian Grove (see seventh article), “gave a major impetus for involving the huge chemical company in the project, a development that had a profound impact on the ultimate success of the whole program,” remembered Nichols.

Van Bush recognized the probable need of a second site for the plutonium reactors. At the Sept. 26 S-1 meeting with Brigadier Gen. Leslie Groves and Nichols attending, DuPont was chosen as the potential contractor to develop and operate a plutonium chemical separation plant. Directly meeting with DuPont, Groves, Compton, and others, Nichols explained similarities between the Pennsylvania Ordnance Works contract DuPont and Nichols previously worked under together (see 5th article) and the proposed Manhattan Engineering District (MED) contract.

“We concluded that we needed DuPont to take on the entire plutonium project [not just the chemical separation plant,]” Nichols recalled. These decisions involving DuPont, as well as various uncertainties involving the plutonium process, would become some of the biggest sources of contention between scientists, industry, and the MED during the war.

The X-10 Graphite Reactor Semiworks in Bethel Valley near Oak Ridge produced the first gram of man-made element Plutonium-239 before moving to the full-scale HEW site in Washington

Nichols recalled, “Our [MED’s] main job was how do you get every bit of information out of the scientists and into the hands of the engineers to construct. You are dealing with groups that never before had contact. … [The scientists] were so highly theoretical. They had to be. …They never worked with engineers before. Of course, no engineer I know of had ever had a group of people like these to work with. …You had these growing pains.

“All during the period of our negotiations with DuPont, Compton was having serious problems with his key scientists … [who] believed they could do the job better. … This problem continued throughout the war.

“I have no question that we tested a plutonium bomb as early as we did only because of DuPont’s role in the Manhattan Project. DuPont’s engineering, construction and production experience was just as essential for success as were the scientific capabilities of the Met Lab.

“On one occasion, Compton asked me to attend a meeting to hear the severe criticisms of DuPont directly from the scientists. … Finally, Enrico Fermi, in all seriousness, strongly recommended to me that we eliminate DuPont from all work except that of the chemical separation plant. He said, ‘If you people will just hire for me the laborers and supply them with brick, I’ll tell them where to lay them.’ Compton responded, ‘If we just had somebody to design the waterworks and the roads, I think I’d almost be willing to back Fermi and take on the technical design.’ Stifling a chuckle, I said, ‘Well, A.H., That’s the one thing I can do. I’m a hydraulics expert and I have built a lot of roads and runways. I can design the waterworks and the roads. Let’s do it.’ Compton started to laugh and admitted, ‘I guess we had better keep DuPont.’”

DuPont thought “there would be only a 50-50 chance of success and a much lesser chance of completing the work before the war ended,” recalled Nichols. Meanwhile Compton gave permission to construct a pile at the University of Chicago’s Stagg Field for Dr. Fermi’s dramatic test on Dec. 2, 1942, which provided proof of creating and controlling a self-sustaining nuclear chain reaction. Nichols,who witnessed a similar demonstration a few days later, recalled, “The autumn of 1942, which included the assignment of Groves and the selection of DuPont and other major contractors, coupled with the first controlled chain reaction, was undoubtedly the most crucial period for the ultimate success of our efforts.”

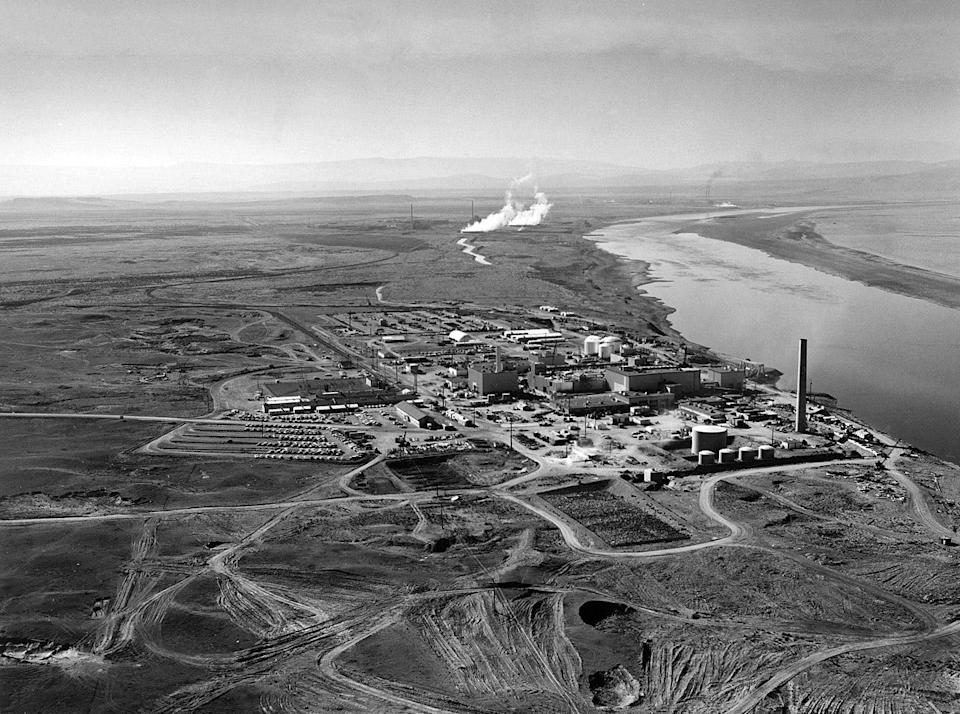

Nichols moved plutonium production from Oak Ridge to Hanford, Washington. Meeting with DuPont officials and Lt. Col. Franklin Matthias mid-December 1942, they discussed site requirements. Hanford had adequate water and electricity plus availability of a much larger area than Oak Ridge. Early in 1943, land was acquired and Matthias, deputy district engineer under Nichols, immediately began construction oversight of the Hanford Engineer Works (HEW) and Richland Village. DuPont’s HEW plant, isolated away from the Met Lab, caused additional discontent with the scientists. Compton could visit HEW whenever he wanted, but others could do so only by DuPont invitation or Groves or Nichols’ approval.

The unenviable negotiations of the DuPont contract fell to Nichols. Eventually, he recalled, “The magnitude and complexity of the DuPont contract would require the approval of the Under Secretary of War.”

Nichols explained, “The crucial issues included the uncertainty of the project’s success, the hazards involved, the dependence of DuPont on the Met Lab, determination of the company to operate the plutonium plants only during the war, responsibility for the liability for radiation health problems that might arise twenty or more years later, and the conservatism of DuPont itself. … possibly … exposing employees to radiation hazards without revealing the full risk to them (due to secrecy) led to DuPont to insist on a form of insurance for each employee. … They proposed and insisted that a trust fund of $20M [an estimated $358M in 2025] be set up in a bank to cover this future liability. This was a large sum in those days and was based on the then-current $10,000 life insurance policy issued to soldiers.”

Uranium slugs for HEW had to “withstand more rugged operating conditions,” recalled Nichols. In addition, National Carbon’s graphite purity sometimes did not meet DuPont’s rigid specifications; Vice President James Rafferty said, “Nichols … I never expected I’d have to let our chief competitor [DuPont] enter any one of our plants.” Nichols diplomatically addressed the problems; production increased.

In October 1943, DuPont released design drawings for the first water-cooled, graphite-moderated reactor. The Met Lab wanted to change designs for four future reactors under consideration. DuPont bluntly asked Nichols, “Is the Army interested in maximum plutonium production or in developing reactor design?” Of course, the answer had to be “maximize plutonium for weapons.”

In March 1944, the first gram of plutonium was produced. Nichols recalled the great excitement: “I felt elated. We were now on the road to success. Compton and Whitaker invited Groves and me down to the [X-10 CEW] semiworks to see it. Compton opened the glass door … to pick up a small glass vial containing a single gram of green liquid. He handed it to me. Whitaker hurriedly … held [a pan] under my hand, saying, ‘For God’s sake don’t drop it on the floor.’”

By May 1944, there were 44,900 people working at HEW. Optimism prevailed until July 17, when Nichols urgently met Groves in Chicago. Nichols recalled the alarming news, “Oppenheimer had abandoned all hope that the gun-type weapon could be used for plutonium. … The good news was that if the implosion weapon could be developed, less plutonium would be required … The bad news was that if the implosion weapon could not be developed, the HEW would be a total loss and the plutonium effort would be a failure and have to be abandoned.

“My concern was Hanford. … I thought that we should proceed at HEW until scientists at Los Alamos determined it was absolutely impossible to develop an implosion bomb in time to be useful in this war. … Groves again demonstrated guts by approving continued construction at the HEW at the same urgent pace.”

By September 1944, ,reactor testing shut down the reactor within hours. After three days working with the Met Lab Nichols recalled, “the scientists discovered they had misplaced a decimal point.” Fortunately, Nichols understood engineering safety factors and previously approved DuPont’s design of creating 500 extra reactor tubes. Nichols recalled, “Upon loading a hundred of the extra tubes, the pile operated successfully. DuPont’s conservative approach had paid off. We were lucky, and the incident showed why we needed many different skills and experiences and various types of organizations all working together as a team to gain success.”

By February 1945, Matthias was shipping plutonium to Los Alamos; HEW and Richland Village were complete. Compton’s champagne dinner bet that he would produce the first kilogram of plutonium in January 1945 was barely lost; but he made good after the war

Quite an effort by the X-10, Met Lab and Hanford teams and their families. Thank you.

Next up: Production Facilities, Part 4 (1942-1945): S-50

Grateful acknowledgements to K. David Nichols Jr.; Ray Smith; Sandy Fye; Dr. Bianka J. Adams, Alisa Whitley, Douglas J. Wilson and the U.S. Army Corps of Engineers Office of History; Michael Stallo; Diane Gulley; Gerald A. Potts; and Bruce W. Scollin for their assistance with this article.

D. Ray Smith is the city of Oak Ridge historian. His “Historically Speaking” column is published weekly in The Oak Ridger.

D. Ray Smith, writer for the Historically Speaking column.

Nuclear reactors line the riverbank, Hanford Site along the Columbia River, January 1960. The historic B Reactor, the world’s first plutonium production reactor, is visible in the distance.

This article originally appeared on Oakridger: Nichols’ diplomacy skills are stretched thin over plutonium production

Read the full article here